Refrigerated Cargo Reefer Handling Guideline

Reefer Handling Guideline

Refrigerated cargoes are usually perishable in nature, highly sensitive to temperature maintenance and likely to have a higher monetary value than most other commodities. The safe and successful carriage of refrigerated cargo critically depends on carriage instructions, which outlines the suitable and most optimum storage conditions during transportation. Although refrigerated cargo include both frozen and chilled goods, the range and diversity of the cargo can be quite extensive, including fresh fruits and vegetables; dairy products; fresh flowers; chilled/frozen fish and meat; etc. Nowadays, many pharmaceuticals are also carried in reefer containers, due to the highly sensitive and valuable in nature of the products. Chilled commodities such as fresh fruits and vegetables; begin deterioration right from the moment of being harvested as freshness gradually decreases. They can also be damaged by low temperatures, either by freezing or by chilling, causing injury to fresh produce. Hence, it makes storing and transporting them very challenging and requires specialized care, expertise and technologies to preserve freshness.

According to Food and Agriculture Organization of United Nations (FAO), about 1/3 food produced in the world for human consumption every year gets lost or wasted, leading to significant wastage of resources (including water, land, energy, labour and capital) and produce greenhouse gas emissions, contributing to global warming and climate change. As one of the leading carriers in refrigerated container industry, ONE has prepared this important guideline to raise awareness among all players involved in cold chain logistics with the goal to minimize amount of losses and food wastage. These recommendations that are considered as widely accepted best practices in the industry for handling any reefer cargo, have been drawn up to assist shippers.

Precool

Precool

While cargo pre-cooling is important; container pre-cooling could be detrimental and lead to cargo damage if not handled properly.

-

Pre-Cooling of Cargo: IMPORTANT

-

All perishable cargo should be pre-cooled to the recommended temperature before loading into a reefer container. Reefer container is designed to maintain within the range of pre-set temperature but not to achieve fast cooling of hot stuff cargo.

-

Loading without precool may cause considerable damage to cargo due to water loss and lead to spoilage for many perishable cargo.

-

If the cargo has been properly pre-cooling, temperature in the reefer container will reach the setting temperature within several hours.

-

-

Pre-Cooling of Container: AVOID

-

In case of precooled container, if the stuffing takes place in open environment then the difference in temperature outside and inside the container will cause moisture on all surfaces of the container when outside humid air flows in during the stuffing; which could be detrimental to cargo. (Picture below) This will dampen the cargo units and could cause the cargo to deform in stowage, possibly resulting in cargo damage.

-

In addition, the moisture produced on the inside of the container and the cargo will result in icing the evaporator coil once the machinery is started. Once the machinery is frosted like this, it will cause a reduction in refrigeration and hamper the airflow which will further delay unit to reach the set point.

-

One exception for Pre-Cooling the container prior to loading is when the cargo is loaded directly from a chilled storage through a tight duct between the chilled storage and the container, it called 'Cold Tunnel'. This direct linkage will prevent any moisture from entering the packing area.

-

Pre-trip Inspection

Pre-trip Inspection

PTI – Pre-Trip Inspection is an extensive inspection done on empty reefer container to ensure that the reefer machinery is running properly at correct settings and that the container is clean and in sound condition, before allotting to customers for cargo stuffing. In ONE, our top most priority is to offer our customers with the most suitable and good quality reefer container for their needs. Hence, ONE follows a strict PTI policy by which all reefer boxes, must pass a thorough Pre-Trip Inspection (PTI) before allotting to our valued customers. Inspections conducted here are to examine the cleanliness of containers, the damages and the condition of refrigeration unit.

In addition, we also have a special PTI policy for high value, high sensitive cargo such as pharmaceuticals which has been carefully designed for preventive maintenance value based on our legacy experience in transportation of High Value commodities.

Air Circulation

Air Circulation

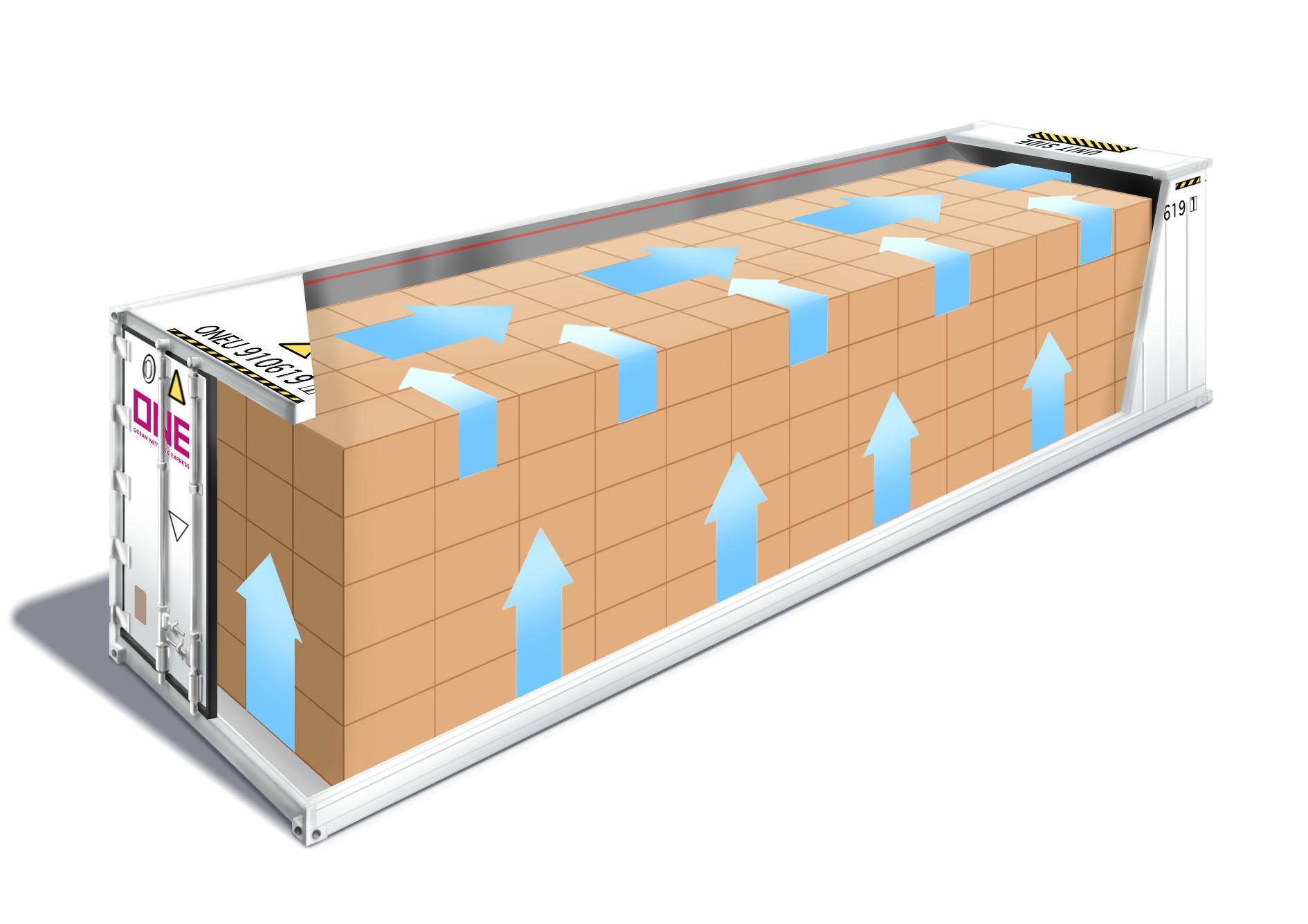

In the refrigerated container, cold air circulates to wrap around the cargo. To maintain this air flow, refrigerated container has rails called T-rails laid on the floor. The cold air blown out from the freezing unit is blown into the T rail from the bottom of the unit and goes towards the door side. The cool air reaches the door, rises, passes through the top of the cargo and returns to the unit.

A red line is drawn on the wall inside the refrigerated container. It shows load restriction and indicates not to load cargo up to the height beyond the line. The red line is drawn near the ceiling and the door side. Loading more cargo over the restriction line Red line, it may lead to a poor air circulation and may not be able to maintain the cold temperature of the cargo. While stowing “Non Palletized” refrigerated cargo in flat-side wall reefer containers, slight loose stowage is suggested for smooth circulation of air evenly around the cargo and also for ensuring that any heat penetrating the container walls does not come into direct contact with the cargo package.

Chilled Cargo

Chilled cargo is highly perishable premium food which can gradually ripen during shipment. In this illustration, the degree of air flow through the cargo is largely dependent upon the stuffing pattern at the door.

Frozen Cargo

If frozen cargo is pre-cooled to the correct carrying temperature, it is only necessary for air to circulate around the periphery of the load. A block stow, i.e., one that has no deliberate spacing between any of the packages or pallets, is all that is required. However, it is necessary to ensure that air can circulate under, over and to each side and end of the stow.

Stowage

Stowage

The cold air that maintains a constant temperature is blown out from the bottom of the rear panel of the reefer unit. Then, the cold air goes through the floor rail (T-bar) to the door side. When it reaches the door, the air is sucked into the top of the rear panel and the air is circulated through the inside continuously. We called the location where the cold air is blown out as “Supply Air”, and the location where the cold air is sucked in as “Return Air”. Thus, do not block the air flow. Please see below Figure #3.

When a huge volume of cargo is loaded, the cold air circulation is entrapped, and it makes temperature control harder. There are Load Limit Mark, Red lines, to indicate the maximum loading capacity on side panels inside the container. Over loading exceeding the “Limited Lines” is prohibited. This Load Limit Mark, Red line, mounted from the ceiling to under 75mm/20ft. and 100mm/40ft. Please see below pictures.

Hence, we never recommend below examples of over loading.

Over Loading

Roof side

Door side

Roof and door side

Short Circuit

Chilled Cargo Stowage Best Practices

Chilled Cargo Stowage Best Practices

- The key is to allow proper air circulation and flow-through so that heat, vapour, CO₂, and other gases produced by the respiration process from chilled perishable products can be removed.

- Proper packaging such as packaging style and package material is necessary to support stacking weight and sustainability at various humidity levels.

- Any packaging accessory like shrink-wrap, slip sheets, foam trays and plastic bags which can block or obstruct air passage should not be used.

- Proper air passage on the package, including proper size/number/ places of ventholes on cartons, is needed to allow refrigerated air to circulate through all the cargo in the container.

- Proper stuffing is required to allow refrigerated air to circulate through the package material and throughout the entire load.

- If the cargo cannot cover an entire floor, cardboard can be used to cover empty spaces to allow for smooth refrigerated airflow.

- There must be no stowage above the indicated red line on the container walls to avoid impeding return air flow.

Frozen Cargo Stowage Best Practices

Frozen Cargo Stowage Best Practices

- As the frozen cargo should have been appropriately pre-cooled to the desired temperature before loading, air circulation should be aimed at blocking and preventing heat penetration from outside the container.

- The entire floor should be evenly loaded and covered.

- Proper corner support of cartons or pallets is needed due to the weight and loading pressure.

- Stowage must be kept below the red-line to avoid air circulation blockage. The key is to allow air circulation around the cargo.

- Ventilation and dehumidification must be set to “Off”. Drain port must be “Closed”.

- Solid block stowage, leaving no space between the packages or cartons, is preferred to avoid hot pot or short-circuiting.

Pre-loading Guideline

Pre-loading Guideline

Before Loading Checklist

- Inspect the reefer container to ensure equipment is in good condition.

- Check and clean T-floor to ensure air channel is clear from the panel to the door.

- Pre-treat the products.

- Pre-cool the products to carriage temperature range.

Note: hot stuffing may damage both the equipment and cargo itself. - Do not pre-cool the container, except when goods are being loaded at a cold facility where these is a sealed connection to the container loading bay.

Note: While reefer cargo is generally classified according to the storage temperature, specific reefer set-points vary according to the exact cargo commodity type.

Booking Checklist

Booking Checklist

Refrigerated cargoes are usually perishable in nature, highly sensitive to temperature maintenance and likely to have a higher monetary value than most other commodities. The safe and successful carriage of refrigerated cargo critically depends on carriage instructions, which outlines the suitable and most optimum storage conditions during transportation. Although refrigerated cargo include both frozen and chilled goods, the range and diversity of the cargo can be quite extensive, including fresh fruits and vegetables; dairy products; fresh flowers; chilled/frozen fish and meat; etc. Nowadays, many pharmaceuticals are also carried in reefer containers, due to the highly sensitive and valuable in nature of the products. Chilled commodities such as fresh fruits and vegetables; begin deterioration right from the moment of being harvested as freshness gradually decreases. They can also be damaged by low temperatures, either by freezing or by chilling, causing injury to fresh produce. Hence, it makes storing and transporting them very challenging and requires specialized care, expertise and technologies to preserve freshness.

According to Food and Agriculture Organization of United Nations (FAO), about 1/3 food produced in the world for human consumption every year gets lost or wasted, leading to significant wastage of resources (including water, land, energy, labour and capital) and produce greenhouse gas emissions, contributing to global warming and climate change. As one of the leading carriers in refrigerated container industry, ONE has prepared this important guideline to raise awareness among all players involved in cold chain logistics with the goal to minimize amount of losses and food wastage. These recommendations that are considered as widely accepted best practices in the industry for handling any reefer cargo, have been drawn up to assist shippers.