Refrigerated Cargo Special Features & Specifications

Controlled Atmosphere Technology

Controlled Atmosphere Technology

The transport of fresh produce is a complicated process because each variety of produce has unique characteristics that are related to recommended temperature, fresh air exchange, shelf life which affects the conditions in which they are carried in a reefer container. All fresh fruits and vegetables are living products and respire. The rate of respiration for any given product will depend on its variety (cultivar), area of growth and the seasonal and climatic conditions experienced during periods of growth. The storage life of produce varies inversely with the rate of respiration, which means that produce with short storage expectancy will usually have higher rates of respiration, eg fresh broccoli, lettuce, peas and sweetcorn. Conversely, potatoes, onions and some cultivars of grapes with low respiration rates have longer storage lives.

COOLXTEND CA+

COOLXTEND CA+

Always Active, Instant Freshness

ONE COOLXTEND CA+ is the most technologically advanced control atmosphere system in the market to extend shelf-life and safeguard freshness of perishable cargoes. Deploying stage of the art VPSA* technology with self-contained nitrogen generator, COOLXTEND CA+ blankets cargo with rich nitrogen to establish optimum atmosphere rapidly. It precisely controls atmospheric composition throughout the transit for produces to enjoy instant freshness preservation and reach distant markets in prime condition. For more information, please refer to our COOLXTEND CA+ customer handout

*VPSA = Vacuum Pressure swing adsorption.

Fruits that benefit from COOLXTEND CA+: Avocado, Blueberry, Banana

COOLXTEND CA

COOLXTEND CA

Under COOLXTEND CA solutions, ONE offers a broad range of different technologies to our customers which helps to control interior atmospheric composition of gasses to delay the ripening process of fresh fruits and vegetables. These technologies are crucial to prolong the shelf life of fruits or vegetables by adjusting the O2 and CO2 concentration of the cargo.

- Special Membrane technology which allows controlled removal of CO2 from atmosphere surrounding cargo to outside of the container.

- Allow ambient fresh air to regulate atmosphere inside container, when respiration lowers O2 setting.

- Vacuum pump creates pressure differential across membrane, exhausts CO2 outside of container.

- Proven its value for banana and avocado cargos, increasing the transportation window to as much as 45 days.

- Ideal for low respiring cargo; where tailor-made atmosphere is aimed via pre-trip gas injection model. An additional controller is monitoring & recording the atmospheric composition inside the reefer.

- O2 concentration by cargo respiration & fresh air injection using valves.

- CO2 Concentration by scrubbers / membrane technology & valves monitors.

- WORLD’S ONLY door-to-door transport system that combines On-demand Ozone Generation capabilities, Real-time Monitoring and Controlled Atmosphere.

- Does not modify O2 & CO2, add ozone ( O3) to kill micro-organisms & control ethylene

- Purfresh is able to continuously generate ozone throughout the voyage, as it uses oxygen from the air.

Cold Treatment / COOLTemp

COOLTemp

Exterminate fruit flies and larvae

ONE COOLTemp technology provides customized in-transit handling process to meet stringent cold treatment protocol. It ensures your fresh produce meet local quarantine requirement by effectively kill fruit flies and larvae with precise control and continuous recording of pulp temperatures (USDA#1,2,3) at different location in the container according to specific cold treatment protocol of importing country. With CoolTemp cold treatment service, it eliminates the need for fumigation and allow fresh produce to enter market faster at optimum condition. For more information, please refer to our COOLTemp customer handout

Fruits that benefit from COOLTemp: Blueberry, Mandarin, Apple, Kiwi, Grape, Citrus, Stone fruit, Lychee, Longan, Starfruit

Fresh Air Ventilation

Fresh Air Ventilation

- Fruits and vegetables will continue to respire and produce heat and other gases (CO2 and ethylene). These gases can induce cargo damage such as discoloration and uncontrolled ripening, resulting in reduced shelf life.

- Therefore, heat and unwanted gases should be removed from the container through ventilation (Air Exchange). Reefer containers can provide vent openings in the 0-250 m3/h range.

- The required air exchange ratio varies from commodity’s respiration rates, ethylene production and sensitivity.

- There are 2 points to remember for setting up ventilator:

1. In principle, ventilator should be closed except when transporting fresh produce (chilled mode).

2. The maximum air exchange rates vary for different reefer machine makers. Hence, it is important to specify desired air exchange rates in M3/Hour (not in percentage %) to avoid confusion.

ONE reefer containers are incorporated with different reefer machine makers to ensure fresh air ventilation for the cargo.

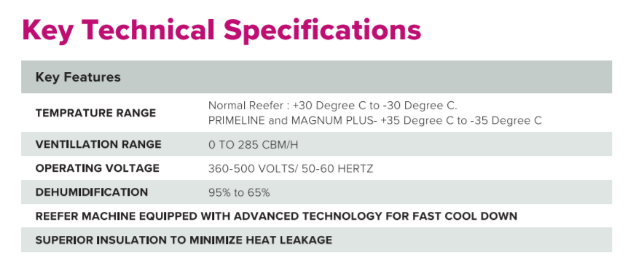

De-Humidification

De-Humidification

ONE reefer containers are equipped with dehumidification function (selectable range between 65% to 95% RH**) in order to prevent germination and decay; which is suitable for transport of some chilled reefer cargo such as fresh garlic, onions, flower bulbs

Key points:

- Reefer machine is only equipped with De-Humidification, so as not to increase humidity inside the container.

- De-humidification is activated should humidity inside the container is higher than the humidity setting.

- The performance of dehumidification depends on type of commodity, packaging and ventilation (air exchanges) and atmosphere condition (i.e. temperature and humidity level). Hence, there is no guarantee to keep the humidity setting.

- Reefer machine is equipped with heating elements and or re-heater coil (depending on machine make) enabling dehumidification.

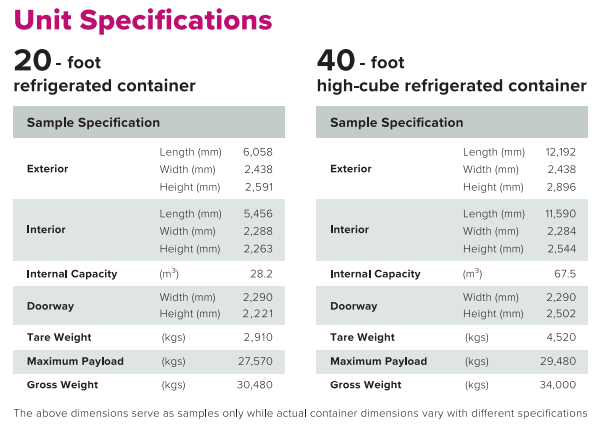

Unit Specifications

Unit Specifications

ONE has one of the largest and modern integrated reefer container fleets in the world. These containers are made of modern materials and advanced light weight refrigeration units which ensure that customers can benefit from higher payload capacity in each container. These reefer containers are mainly of two sizes i.e. 20ft and 40 HC and built according to stringent testing and highest technical standards.

The refrigeration unit is built onto the nose of the container and power is provided by a motor generator (when container is on wheels), by terminal (when grounded in a yard) or by the ship (when laden on board). Air, cold or warm, is supplied to the inside of a container via an air duct system that enters the container from the bottom. Air circulates under, over and through the load before it returns to the refrigeration unit. This circulation is repeated continuously when the unit is in operation.

In the nose of each refrigeration units are adjustable ventilation holes. At specific settings, these vents allow fresh air exchanges to avoid a build-up of carbon dioxide inside the container. All fresh fruits and vegetables are living products and as a result, emit heat and carbon dioxide. Vents allow this warm toxic air to be expelled from the container to avoid spoilage. These advanced reefer containers are computerized, enabling highly precise temperature control. Transportation has become easier due to this type of precise control that ensures preserving the quality of foods such as meat, fish, eggs, vegetables and fruits, as well as films, plants and pharmaceuticals.

Non-Operating Reefers

Benefits of Non-Operating Reefer (NOR) to Customers

Every year container shipping industry spends billions of dollars carrying empty reefer and dry containers to market demand locations around the world – which is logistically challenging and also inefficient in operations. NORs offer an opportunity to solve this problem thereby also contribute to reducing container shipping industry’s carbon foot prints.

Offering of Non-Operating Reefer (NOR) or Reefer as Dry (RAD), is to minimize empty reefer repositioning cost in Dry Dominant/Reefer Non-Dominant legs, especially out of Asia. ONE allows the use of reefer containers in non-operating mode to carry “approved” dry cargo to reefer demand origins. This type of cargo is known as NOR or RAD and is approved for packing into refrigerated containers for transportation without the refrigeration machinery being switched on. ONE’s NORs transport your dry cargo in a clean, food-grade insulated container with capabilities to protect against extreme shift in outside temperature.

SUPERIOR QUALITY OF CONTAINERS:

Reefer containers are generally used to carry perishable commodities only; hence quality and cleanliness of the containers surpass that of normal dry containers.

MINIMIZE TEMPERATURE FLUCTUATION:

Due to higher insulation quality of a Reefer container, NORs minimize temperature fluctuation impact to cargo during day and night. Typically commodities which are sensitive to temperature fluctuations are Chemicals/electronics devices/films/beans in bags etc.

PROTECTION AGAINST CONDENSATION AND MOISTURE:

Due to higher insulation quality of a Reefer container, NORs also provide protection to cargo against condensation and moisture.

IMMEDIATE BOOKING ACCEPTANCE, EQUIPMENT GUARANTEE, LOADING PRIORITY:

In trade lanes where ONE face typical reefer equipment imbalance, using NORs can also provide benefits to shippers such as immediate booking acceptance, equipment guarantees, loading priority over dry (although 'live' Reefer boxes will always take priority over NORs). Contact your ONE Local Sales representative for further details about ONE preferred port pairs to avail such benefits.

COMPETITIVE PRICING:

Possibility of better pricing compared to DRY at ONE Preferred port pairs. Contact your ONE Local Sales representative for further details about ONE preferred port pairs to avail such benefits.

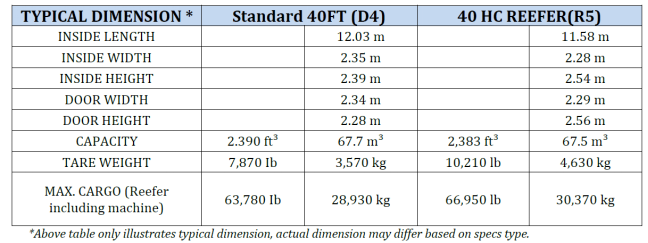

MINIMAL DIMENSION DIFFERENCE BETWEEN 40 FT STANDARD DRY CONTAINER AND 40 HC REEFER CONTAINER

For more information, please refer to Non-Operating Reefer Brochure

CONTROLLED ATMOSPHERE

ONE’s COOLXTEND CA+ and COOLXTEND CA atmosphere management system offers a range of solutions to meet our perishable customers demand. With the help of such advance technologies it’s possible to control the internal atmospheric gas composition which in turn helps to prolong the shelf life and maintain the quality of fresh produce, enabling our customers to expand into new distant markets. We have the best solution available for your perishable produce.

At ONE we understand that reefer cargo requires a high degree of expertise and careful handling to preserve cargo freshness and extend shelf life, especially for perishable fresh fruits and vegetables segment. Providing you with best in class reefer containers, equipped with cutting edge latest technologies, is our top priority.

Atmosphere ( COOLXTEND CA+ & COOLXTEND CA Solutions)

ONE’s COOLXTEND CA+ and COOLXTEND CA atmosphere management system offers a range of solutions to meet our perishable customers demand. With the help of such advance technologies it’s possible to control the internal atmospheric gas composition which in turn helps to prolong the shelf life and maintain the quality of fresh produce, enabling our customers to expand into new distant markets. We have the best solution available for your perishable produce.

Cold Treatment (COOLTemp solution)

ONE’s COOLTemp solutions offers cold treatment (CT) or cold sterilization option to our customers - which is an important post-harvest solution aimed to disinfest fruits subject to the fruit fly or other damaging insects. ONE’s advanced reefer containers can offer manual as well as automatic CT (ACT) option to our customers from various origins to comply with destination country’s quarantine guidelines.

Fresh Air ventilation

Fresh Air ventilation is an automated system designed to remove heat and unwanted gasses released from produce respiration inside a reefer container via the fresh air vents. ONE operates one of the largest reefer container fleet equipped with Fresh air ventilation ventilation capability.

Dehumidification

ONE reefer containers are equipped with dehumidification function (selectable range between 50 to 95% RH**) in order to prevent germination and decay; which is suitable for transport of some chilled reefer cargo such as fresh garlic and onions.