OPERATIONAL EXCELLENCE

- GREEN STRATEGY

- Sustainable Shipping Solutions

- GOVERNANCE

- OPERATIONAL EXCELLENCE

- SUSTAINABILITY REPORTS

Operational Excellence

Operational excellence is a mindset and way of working that we embrace at ONE.

When we first started operations in 2018 as one of the newest players in the industry, we knew we had to bring our best to the table to successfully compete in the market. This strategy has enabled us to strive for sustainable improvements within our operations and high levels of service quality.

RAISING THE BAR ON SERVICE QUALITY

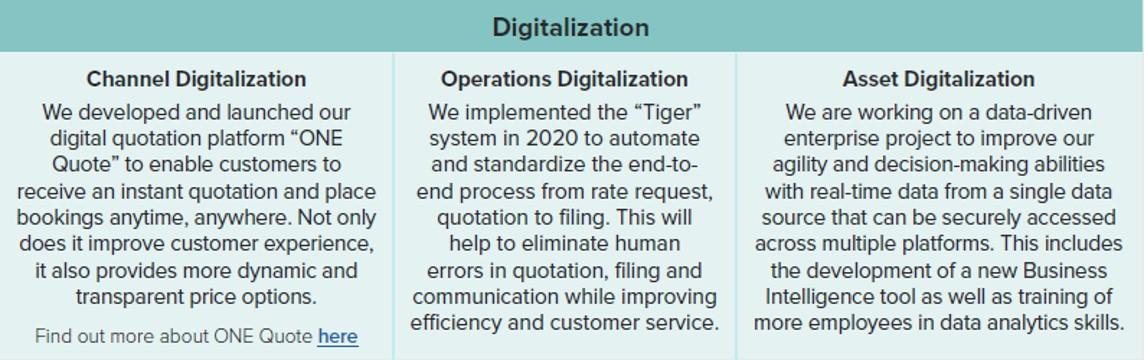

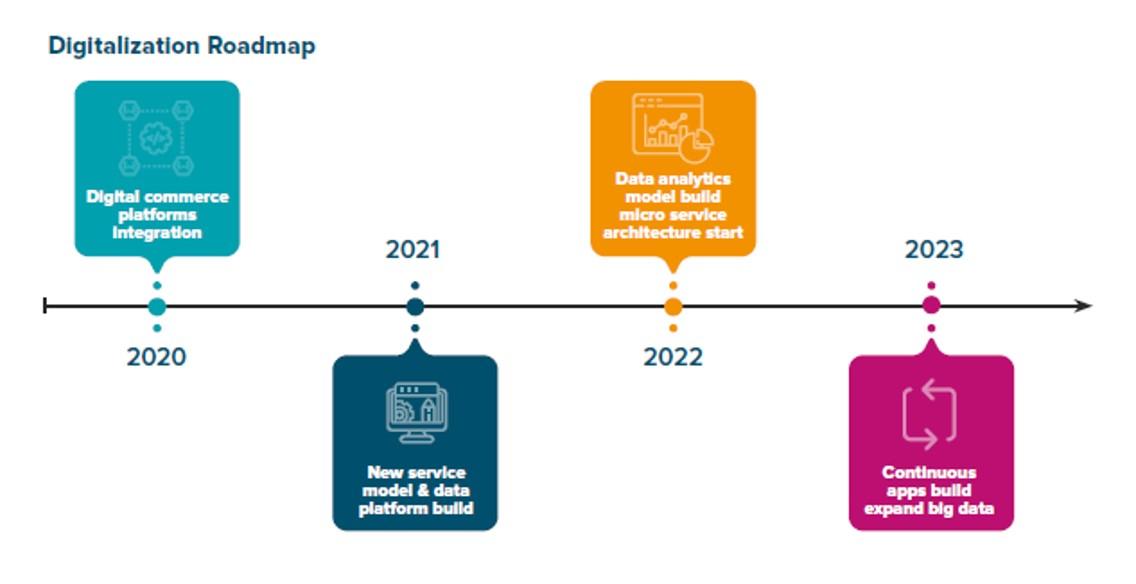

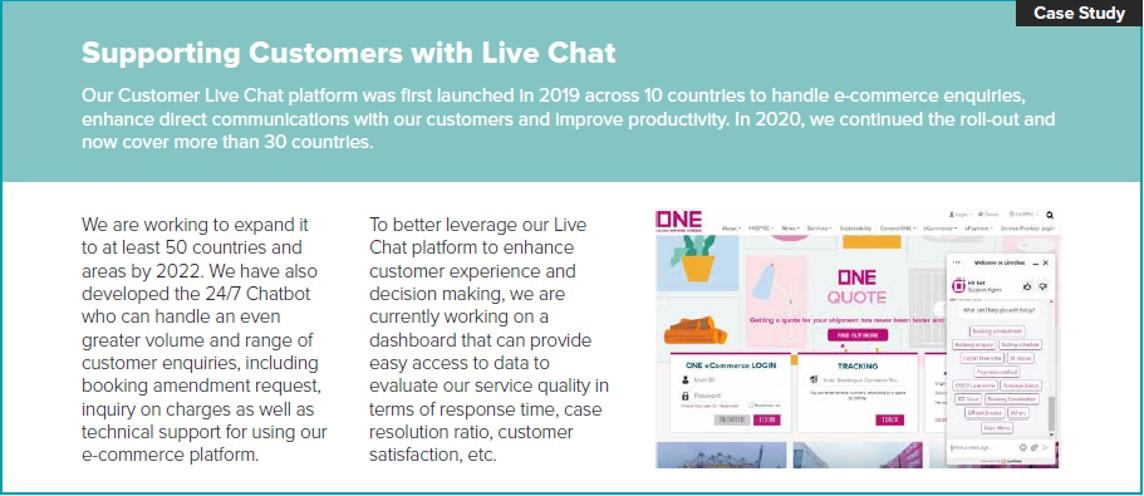

Innovation and digitalization are critical enablers of operational excellence at ONE. In 2019, we established our Digital Strategy Committee and Digitalization Roadmap, to build our digital capabilities and enhance existing business models and services, with a focus on delivering better customer experience and operational efficiency.

DELIVERING BETTER CUSTOMER EXPERIENCE

We commenced the first stage of our Digitalization Roadmap in December 2020, digitalizing our channels, operations and assets to provide an end-to-end customer experience within a single digital environment from quotation to e-invoice.

We continue to enhance our Customer Relationship Management (CRM) system to provide full visibility of customer information and interactions across global and regional offices for key accounts, in order to improve customer communication and experience. We also started deploying Robotic Process Automation (RPA) for our booking documentation process to improve quality, accuracy and turnaround time. We aim to have 100% of customer bookings done via our digital platform by 2025.

MAINTAINING OUR OPERATIONAL EDGE

High levels of customer satisfaction and service quality cannot be met if we do not execute on-time delivery of our customers’ goods. That, in turn, requires us to achieve the best operational efficiency at sea and on land.

One of the initiatives implemented is the ONE Agile Supply Chain Integrated System (OASIS) which is a centralized inventory management system that uses data analytics to forecast container demand and supply from shippers (export) and consignees (import) so we can optimise our container positioning strategy. It has been implemented in 99% of locations in ONE’s depot network, with realized savings on equipment cost and empty container reposition costs.

Another initiative is our Terminal Partnership Program (TPP), launched in 2018 to partner terminal operators to improve productivity and service reliability through close cooperation on scheduling, stowage planning and equipment deployment. It is now expanded to more than 10 terminals including a number of major terminal operators all over the world.

CARGO AND CONTAINER SAFETY

The safe transportation of cargo is fundamental to delivering the highest standards of customer service and enabling a smooth flow of operations. It also protects ship and land crew from unnecessary harm. We ensure safe cargo transportation and operations onboard by enforcing strict safety standards and inculcating safety awareness in our employees and contractors.

ONE’s stringent Vessel Quality Standard (VQS) drives our approach to vessel safety. The VQS ensures high safety standards are maintained on ships, based on requirements for ship safety and quality management systems that are in line with industry standards.

To ensure the safe operation of ships, we developed and implemented an Operational Standard to provide guidance to ship crews on how to manage and respond to issues such as cargo damage, heavy weather, accidents and fires, as well as on safe navigation of areas at high-risk of piracy and conflict zones. Issues such as robbery and theft, unauthorized stowaways, and the smuggling of firearms, drugs, and other illegal contraband are also addressed in the Operational Standard.